Karlsruhe Research Factory: Optimizing Industrial Production with AI

-

author:

Melanie Klagmann

- date: 05.10.2022

Karlsruhe Research Factory: Optimizing Industrial Production with AI

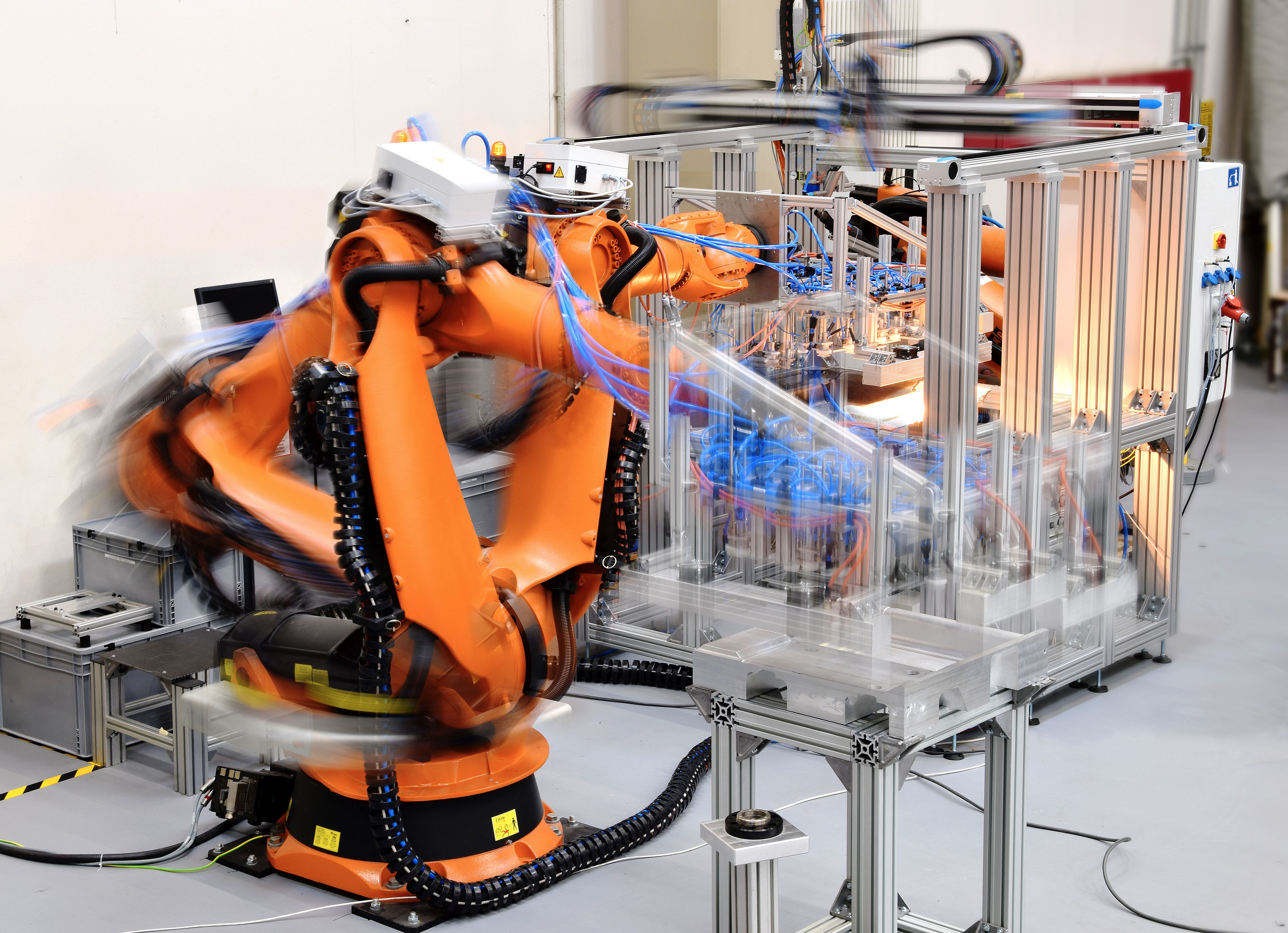

Machining of fiber-reinforced plastic components in the Karlsruhe research factory. (Photo: wbk, KIT)

Ever shorter product life cycles and volatile markets are forcing companies to manufacture high-quality products quickly using new, immature processes. Comparable to software, which is constantly developed further by updates during use, the production processes for this must be improved during operation: This is the goal of researchers at the Karlsruhe Research Factory for AI-integrated Production of the Karlsruhe Institute of Technology (KIT) and the Fraunhofer Gesellschaft. With the help of artificial intelligence (AI), they want to significantly shorten the time until these products reach the market and save costs.

Sophisticated production processes are necessary for companies to be able to produce in a high-quality and cost-efficient manner. Because many different factors have to be taken into account for this, their development has been particularly costly up to now - especially if new materials and processes are used, the production process is highly complex or no mature models are available. The systematic use of AI should make process adaptations cheaper, faster and more efficient. This is the goal of the research group "AI-based Methodology for Rapid Upgrading of Immature Production Processes" of KIT and Fraunhofer Gesellschaft. It wants to make it easier for companies to penetrate new production processes in fields such as lightweight construction or electromobility more quickly in the future, and to change or adapt them in a targeted manner. Using the production of fiber-reinforced plastic components, for example for the automotive sector, the team wants to show how AI methods can be used to increase process maturity and product quality in a short time and during operation.

Designing and "over-instrumenting" processes: how AI learns quickly

"We first look at the process of forming semi-finished fiber products. These are flat fabrics that are used as starting material for the production of components. Here, manual rework such as reheating or forming is currently necessary until the right process parameters and steps are found and set," says Professor Jürgen Beyerer from the KIT Institute of Anthropomatics and Robotics and director of the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB. "The goal is to understand the process as quickly as possible so that we can use this as a basis for regulating the process in such a way that products with good quality are created sooner."

To do this, the team is equipping the production process with expanded actuator and sensor technology - for example, robotics and additional measuring instruments. This is called "over-instrumentation." The goal is to capture as much information as possible, such as temperatures, pressures or forces. Depending on the prediction of a self-learning model, the variables needed for process control can then be identified. "We want to systematically equip immature processes so that an AI can learn relatively quickly how process parameters and outcome relate to product quality," Beyerer said.

Getting processes right: AI makes recommendations

To avoid having to repeat this process for each individual process, the researchers want to generalize the findings and develop a construction kit that can be used for all similar processes. Dynamic modeling will be used to create a digital image of the process based on data, so that the database can be tested in advance. "The resulting approach for the rapid maturation of production processes that have not yet been fully specified also makes it possible to quickly transfer the findings from research to industry: companies are given both a procedure for quickly adapting their processes and ways of measuring the process maturity," says Professor Jürgen Fleischer, head of the wbk Institute of Production Technology at KIT.

With their novel approach, the research group prevailed in a tough competition: As one of eight groups in the "Artificial Intelligence" strategic funding initiative endowed with 90 million, the German Research Foundation (DFG) is funding it with 4.79 million euros for four years. Following a successful review, an extension for a further four years is planned. The project will create doctoral positions in mechanical engineering, computer science, mechatronics and industrial engineering. The research group will start work on January 1, 2023.

As "The Research University in the Helmholtz Association", KIT creates and imparts knowledge for society and the environment. The aim is to make significant contributions to global challenges in the fields of energy, mobility, and information. To this end, about 9,800 employees cooperate on a broad disciplinary basis in natural sciences, engineering, economics, and humanities and social sciences. KIT prepares its 22,300 students for responsible tasks in society, industry, and science through research-oriented university studies. KIT's innovative activities bridge the gap between knowledge and application for the benefit of society, economic prosperity, and the preservation of our natural resources. KIT is one of the German universities of excellence.

kla, 05.10.2022